text.skipToContent

text.skipToNavigation

Simplified Motion Series consists of different electromechanical components together with a simple and application-optimised combination of motor and servo drives, the so-called integrated drive. This solution does not require an external servo drive. The electric alternative for very simple movement and positioning tasks does not require the usual commissioning process that is needed for traditional electric drive systems, which can often be quite complex. It also offers special movement characteristics such as gently cushioned retracting into the end position, or simplified press-fitting and clamping functions.

This is quick and easy without the need for any software, computer or other accessories, because all parameters can be set manually directly on the drive. Simplified Motion Series is then connected directly to the controller, either via digital I/O (DIO) or IO-Link®, both of which are integrated as standard.

Highlights of the Simplified Motion Series

The EPCS is suitable for single linear movements in every mounting position and its smoothly running ball screw drive allows precise and rapid positioning. As an extremely cost-effective complete solution, the electric cylinder is ideally suited for applications such as positioning or clamping, distribution, sorting or ejection, and in handling systems as a simple Z-axis.

![]()

Festo Simplified Motion

Simplified Motion Series consists of different electromechanical components together with a simple and application-optimised combination of motor and servo drives, the so-called integrated drive. This solution does not require an external servo drive. The electric alternative for very simple movement and positioning tasks does not require the usual commissioning process that is needed for traditional electric drive systems, which can often be quite complex. It also offers special movement characteristics such as gently cushioned retracting into the end position, or simplified press-fitting and clamping functions.

Commissioning

This is quick and easy without the need for any software, computer or other accessories, because all parameters can be set manually directly on the drive. Simplified Motion Series is then connected directly to the controller, either via digital I/O (DIO) or IO-Link®, both of which are integrated as standard.Highlights of the Simplified Motion Series

- Simplified functionality for simple movements

- A variety of movements with different mechanical systems

- Integrated products eliminate the need for a control cabinet

- Quick and easy commissioning without software

- No special expertise required for commissioning

- Digital I/O (DIO) or IO-Link® integrated as standard

Electric cylinder EPCS

The EPCS is suitable for single linear movements in every mounting position and its smoothly running ball screw drive allows precise and rapid positioning. As an extremely cost-effective complete solution, the electric cylinder is ideally suited for applications such as positioning or clamping, distribution, sorting or ejection, and in handling systems as a simple Z-axis.

- Three sizes with a max. stroke of 500 mm

- Simple and cost-effective position sensing with proximity sensor, flexible, reliable and quick to mount, can be retrofitted or repositioned at any time

- Optional: ducted compressed air compensation prevents particles or moisture from entering and particles leaking into the environment

- Unique "one-size-down" assembly system in conjunction with the spindle and toothed belt axes ELGS-BS/-TB

- The motor can be rotated 4 x 90° – this can be modified at any time

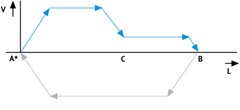

Basic profile for movement between two end positions: with speed control

Expanded movement profile for simplified press-fitting and clamping functions: with speed and force control

You might also be interested in this:

Festo servo drive

Read further

Servo drive CMMT-AS/CMMT-ST and servo motor EMMT-AS. Complete drive system, consisting of servo drive and servo motor, with seamless connectivity in hardware and softwar

Festo DGST

Read further

Small but strong: the DGST is the smallest of its kind and the shortest slide drive on the market. However, it is strong when it comes to precision, forces, motion control, durability and reliability. For maximum torsional rigidity, the yoke and slide are a single part and the sensors and cushioning are fully integrated.

SKF Blue Line

Read further

Food grade is commonly considered to be the equivalent of having food-grade seals, food-grade lubricant and corrosion-resistant bearing units.

VLT Midi Drive FC 280 AC drive delivers precise and efficient motor control for machine builders in the food and beverage, material handling, and processing industries. It is strong on control performance, functional safety, and flexible fieldbus communication. It’s also an easy retrofit for the VLT 2800 in established plant or machinery concepts.

Check out our other success stories:

-

Van Meer - Quick Connection for Energy StorageRead moreDrive specialist Van Meer developed an energy storage system for heavy-duty drives and designed a custom battery system for it. For the connectors in the battery system’s cabinet, their regular supplier itsme recommended omni-brand partner Phoenix Contact. Excellent connectors — only the frame didn’t fit. Phoenix Contact quickly developed a customer-specific connector design. itsme now supplies Van Meer with complete connector sets, including the custom plug.

-

Avebe - A Good Night’s Sleep Thanks to FactoryScanRead moreCompanies often have no clear idea of the installed base of industrial automation in their factories and warehouses. With FactoryScan, itsme can provide an overview of the current status of automation components such as PLCs. Potato processor Royal Avebe uses the results to update their component stock and assess future availability. The scan is intended to reduce the number of hardware-related disruptions Process Control Engineer Johan Wierenga has to deal with. It also helps him sleep better, knowing the stock is up to date.

-

Elektro VV - The right expertise in the right placeRead moreElektro VV, based in the Belgian province of Antwerp, carries out general electrical work and solar panel installations for both companies and private individuals. For complex projects, the company calls on Breemes, which brings expertise such as low-voltage studies. “The challenge is to design a panel that can be built quickly and efficiently, and is future-proof.”

-

OI - Warm relationship with supplierRead moreThe O-I glass factory in Leerdam produces 3.5 million beer bottles every day. The challenge of keeping production running 24/7 is tackled together with trusted supplier itsme. They ensure that technicians never run out of stock during maintenance and that critical components like cables and sensors are heat-resistant. This makes life much more relaxed for supervisor Patrick Maduro and his team in the electrical engineering department.